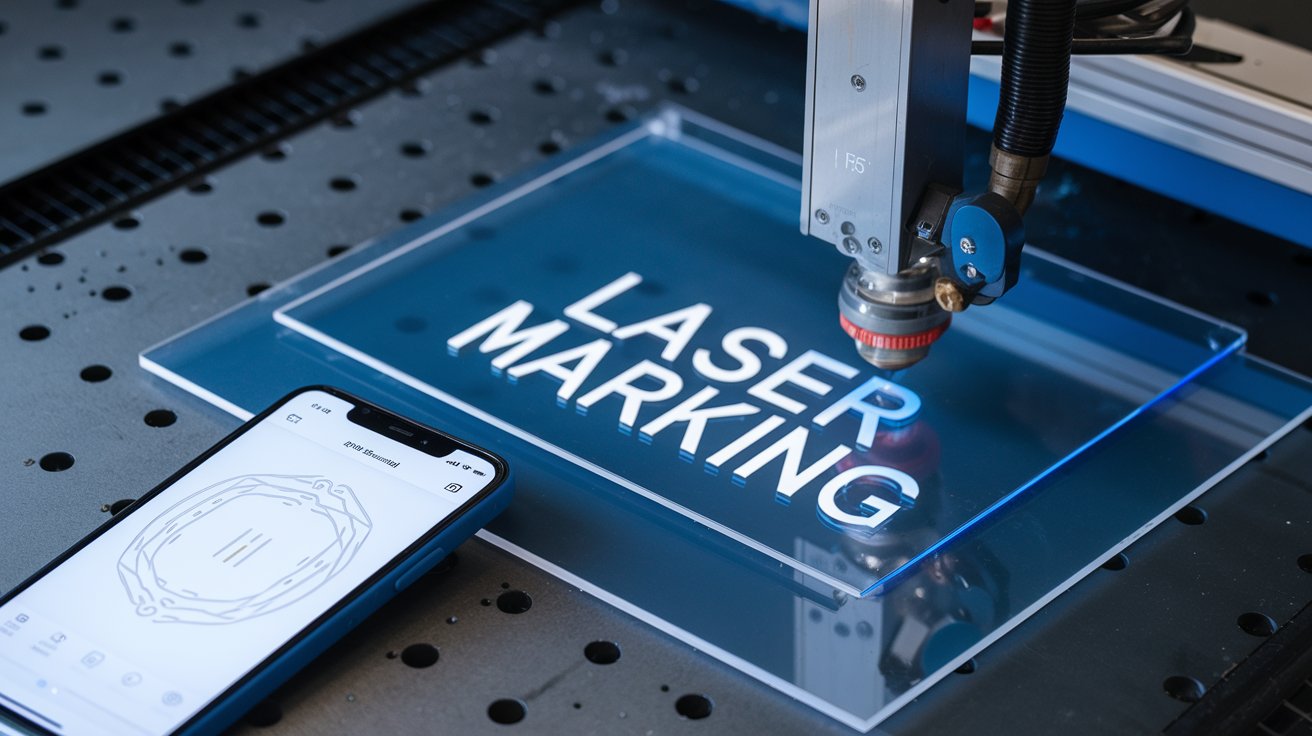

Laser Marking. If you think tablet and smartphone apps are all fun and games, you aren’t up on the latest apps. Just when you think that apps have come full circle, some genius comes up with one for laser cutting applications.

During critical laser-cutting applications, technicians sometimes have to peer into the protective window of the laser-cutting machine to check for kerf creation and piercing problems. Now, you are more likely to see technicians checking their smartphone or tablet instead. That’s because they’re using an app to check for signs of trouble.

Troubleshooting is Imperative but Challenging Laser Marking

Due to the nature of laser cutting, technicians must stay on top of any changes in the substrate being cut to ensure a precise, even, clean kerf. The conditions of various materials can change, even slightly, which will affect the cut. This especially happens near the bottom cut of a thick piece of material. If the technician sees dross or rough striations, the molten metal isn’t evacuating as it should.

The troubleshooting of bad cuts isn’t an easy thing to do. However, new technology is making it a little bit easier for technicians. Technologies that diagnose issues with piercing and cutting are one way to make it easier to troubleshoot. Likewise, Bluetooth technology combined with laser technology allows operators to look at the data and interpret it at any given moment during the cutting process.

Industrial Use and the Future of Laser Marking

This app technology is currently only used for industrial laser cutting processes, but who knows when it will be made available to the general public for processes like laser marking, etching, cutting, and engraving. You can already use your tablet or computer to program what you want these machines to do. It’s not such a far-fetched idea that more data and more technology can be included over time.

Not every laser marking system brand has incorporated smart app technology, but it’s coming. It will soon be a standard in the industry across all brands in all industries around the world. Instead of technicians having to physically watch the laser cutter, they can monitor, maintain, and troubleshoot most problems they find right from their tablet or smartphone.

In the not-so-distant future, small business owners and home businesses will likely have more access to laser machines that come with an app they can use to boost productivity and performance across laser applications. Some of this technology is already available, but is limited or in trial mode, so only some users are testing it.

The Limitless Possibilities of Laser Marking

Just imagine the possibilities for growth in the laser engraving industry once this technology takes off and becomes the standard. Small businesses and large manufacturers will be able to produce more, lose less product, work faster, and provide higher quality products and services to their clients and customers.

If you’re considering starting a laser engraving or etching business, consider the current investment is relatively small in comparison to many other businesses. Getting in before advancements in technology occur could give you the edge as it unfolds.